Hangzhou Guofeng Technology Development Co., Ltd

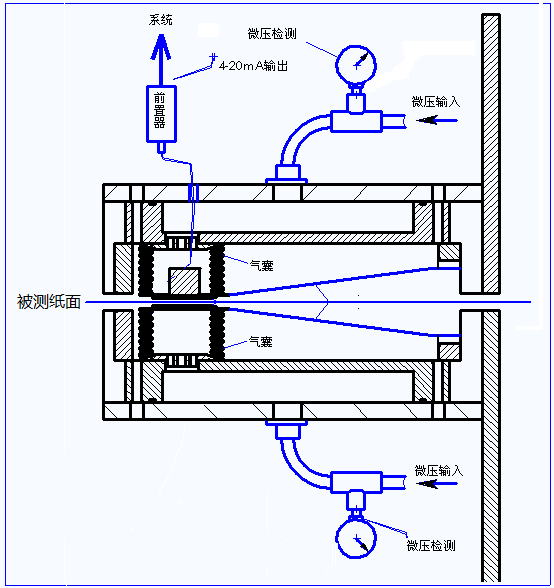

Structure Diagram of the GF-CLP Finished Paper Thickness Sensor

Appearance Diagram of the GF-CLP Finished Paper Thickness Sensor

Field Service Effect Picture of the GF-CLP Finished Paper Thickness Sensor