Hangzhou Guofeng Technology Development Co., Ltd

Introduction to System

The sizing and boiling process is a complicated multi-reaction process, which is affected by a variety of parametric variables. Therefore, the purpose of automatic control of the boiling process is to properly adjust the major influence factors, stabilize boiling conditions and on this basis, conduct an optimized control on parametric variables in the boiling process in order to produce paper pulps featuring consistent and high quality, high yield and low consumption.

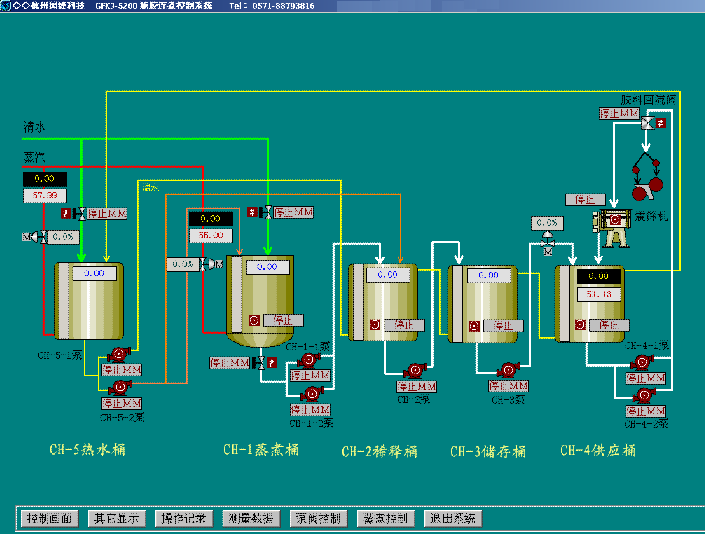

The DCS control system for sizing and boiling comprises sizing material reaction apparatus, sensor, CPU, control valve and sizing material pump. The sensor is connected with the input end of CPU. The control valve and the sizing material pump are connected with the output end of CPU. The sensor is set in the sizing material reaction apparatus. The check valve is connected with the front end of sizing material reaction apparatus. The sizing material pump is connected between two sizing material reaction apparatuses. A sensor is set in the sizing material reaction apparatus to detect temperature, concentration and liquid level inside the apparatus and send the results to the CPU which will control the startup and shutdown of the control valve and the sizing material pump. Highly automatic control on boiling, diluting, storing and loading of sizing materials reduces labor cost with increased production efficiency and promotes paper surface sizing level, resulting in improved paper quality.

Site Pictures

Man-Machine Interface